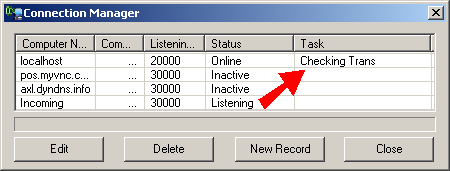

Good. Now run both POS and Control so that they are online, and just wait a moment or two so that Control has retrieved all transactions from the POS. You will see the "Task" for the terminal in Connection manager cycle through, and you will know it has collected all the transactions when it goes through "Checking Trans" and then moves on to "Checking Departments", without going through "Recvd Seq NNNN". This means there are no transactions waiting to be collected from POS.

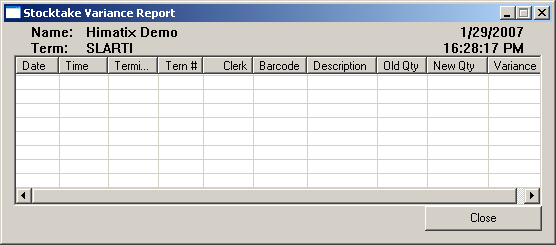

OK. Now close Connection Manager and Order Manager (if it is open), and then go to the File Menu, Choose Utilities and then Clear Stocktake Variances. This clears old stocktake data from previous stocktakes. Once this is done, run Connection Manager again, and the choose Print->Inventory Reports->Stocktake Variances. You should see an empty report something like this.

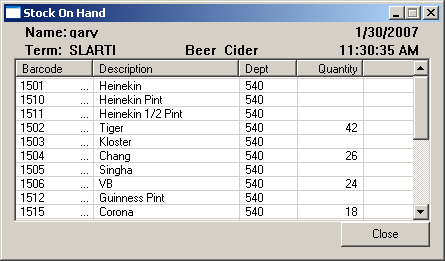

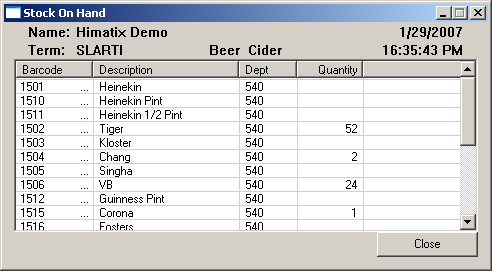

Good. That means that everything has been cleared properly. Now go to Print->Inventory Reports->Stock On Hand and do a report for one of the departments, and you will see a report something like this.

Firstly, process a sale of one of the items that appears in the Stock On Hand Report. Tiger had 52 according to the stock on Hand report, so lets process a transaction to sell 2 of these.

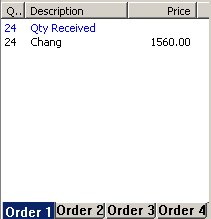

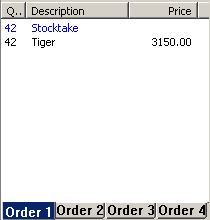

Now, after selling these Tiger's, lets do a stock count for Tiger. In POS, Click on "Input Screen" and then 42 on the numeric display followed by "Stocktake". You will see that the top line of the Sale shows "42 Stocktake". Now act as if you were selling a Tiger. Navigate to the screen where the Tiger button is displayed, or barcode scan it or whatever. You will then see that the Sale shows something like this:-

Now, let's do a stocktake for another item. This time, lets use Corona, and in this example we will enter a quantity of 20. Same keying sequence on the POS.

Input Screen

20 Stocktake

"Sell" the item.

Now, after doing the stocktake for Corona, lets sell 2 Coronas in the normal way and have a look at the results.

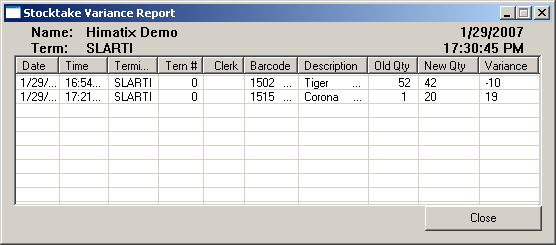

With Tiger, the original quantity on hand was recorded as 52. We sold 2. Then we entered a Stocktake Quantity of 42. But the sale was processed before the stock was counted, so the quantity of Stock on Hand should be 42. Correct?

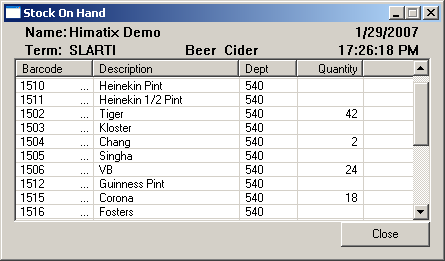

With Corona, the original quantity on hand was 1. We entered a Stocktake Quantity of 20. Then we sold 2. But in this case, the sale was entered after the stock was counted so now, the quantity on hand should be 18. Correct?

Lets go back to Control. If you have been watching Connection Manager while these transactions have been processed, you will have seen a few "Recvd Seq NNNN" messages appear in Connection manager. If you had closed Connection Manager, then open it again with POS running, and wait for the transactions to come through.

Now lets run the report for Stock on hand for the same department.

Think about what you have just done!

You have just done a stocktake while trading was taking place, and the quantities have been processed correctly.

The reason why retailers need to close the doors, or perform stocktakes outside normal trading hours using other POS systems, is that they have no way to tell if an item is sold before the stock was counted or afterwards. Therefore they can't count stock and trade at the same time.

But with SELLmatix, because you can enter stocktake quantities through the POS, you can trade and count stock at the same time.

The only thing you need to be aware of is a situation where a customer picks an item from the shelves and still has the item in their trolley when the count is performed, and they process the sale after the stocktake figure is entered.

Think about what this means for your business. You save money on overtime because stocktakes can be done during business hours when trading is slow, instead of after hours. You can easily do small stocktakes over a department instead of doing everything in the shop at the one time. This lets you monitor areas where problems are likely to occur, and identify losses when they happen.